Waste Audit Survey Question: What Your Company Throws Away

Our Waste Audit Survey found many operations throw recyclable material in their dumpsters when they could be getting revenue from recycling it instead.

Responses to our recent Waste Audit Survey indicated that 17% of those surveyed have no equipment to help them recycle. One-third put all their trash in a dumpster, and regularly pay waste haulers to pick it up. These respondents may not have the information they need to recycle efficiently, or may not have a solid, goal-oriented recycling program. What’s more, a lot of businesses do not currently work with a recycler. But Mid America Paper Recycling can help them move forward to create a more sustainable business with a first-of-its-kind program that effectively benchmarks, monitors, and upgrades a company’s’ recycling operations continuously. “There are proper tools for the job,” explains Mid America Paper Recycling President Paul Pirkle. “Dumpsters, compactors, gaylords, tubs, balers, et al, are all equipment types used by companies in their recycling processes. Using these tools effectively is critical. The best practice is advising a company in those ways to best manage their generated waste so they can reduce their costs while increasing their revenues.”

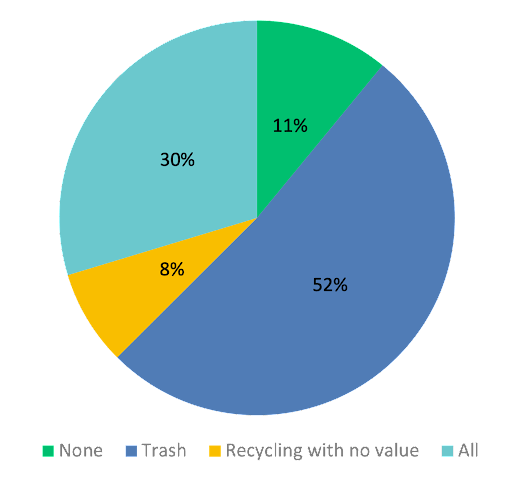

Q10: What materials are generally disposed of in your dumpster?

Mid America Paper Recycling’s recycling programs guide your employees on proper recycling techniques and encourage them to commit to sustainability. “The main purpose is to educate everyone in the company about the benefits of recycling and provide them with best practices to reduce their waste and increase its worth,” says Paul Pirkle President of Mid America Paper Recycling. “We collaborate closely with operators to help them identify where their waste is generated, establish key collection procedures, and set objectives that will continually improve their waste stream’s revenue contribution to the business.”

There’s value in paper waste

“Many of the materials thrown in a dumpster can be recycled,” Pirkle explains. “We can help these firms develop a company-wide recycling program that diverts valuable recyclables from the dumpster. This waste instead can be baled and recycled, which drives revenue, costs will decrease as the frequency of use of the dumpster decreases. Recycling reduces the indirect costs associated with dumpsters and turns waste into a product that has value.”

Independent companies across the country have many recycling service options available to them and may have only recently placed an emphasis on recycling, Pirkle points out. “We can turn their mindset toward recycling, where they learn good recycling habits that will help them grow for years. We can help them transform from a cost center to a profit center. We give them a sustainable process of sorting, organizing, and managing their paper waste. Using gaylords, totes, and the right baling equipment can also reduce labor, save space, and keep waste under control.”

Generating revenue

Pirkle points out that one manufacturing operation can generate hundreds of tons of industrial paper and plastic waste annually from their operation. “This waste can generate significant revenues for the company” he says.

“While most operations have no communication with their waste hauler, 22% of our Survey respondents say they’re not informed at all about when their recycler will make pickups. And 44% say they receive ‘average service ‘while only 14% say they receive ‘excellent’ service. We visit our clients regularly to see how they’re doing and continually suggest improvements that can be made to their operation,” Pirkle adds. “We not only report to the accounting departments to reconcile what has shipped, but we report through our business intelligence platform to work with our customers’ operations team so that we can directly impact the manner in which they work. This process encourages relationship building and allows our customers to benefit from our 96-year history through continual education. This process ensures they take all the proper steps to recycle their waste effectively and economically. Our Audit Process can help these operations realize significant revenues.”

Small to large companies can streamline their waste recycling methods, reduce labor, time, and expenses with help from Mid America Paper Recycling. “No company is too small or too large to have a sophisticated recycling program,” Pirkle explains.

“We provide them with a score and a taxonomy [classification] level of their recycling effectiveness. We then let them know what they’re doing well and how they can improve,” Pirkle mentions. “They learn the capabilities of baling machinery and how to maximize its efficiency, while we arrange for their baled waste to go directly to a paper mill. These improvements streamline their recycling process, so they reduce the number of dumpsters pickups, while reducing their indirect costs and hopefully provide a new revenue stream.”

Focusing on continuous improvement

Businesses that take the Waste Audit and partner with Mid America Paper Recycling will benefit from the increased education of how they can better manage their waste generation within their facility. This can improve their recycling processes and uncover new revenue streams by getting a solid handle on recycling.

Request a free, quick Waste Audit Survey today—visit https://www.surveymonkey.com/r/MAPRAudit.