Gaining Traction in Recycling with First-Ever Quality Initiative

“We call it growing the financial worth of their waste,” explains Mid America’s President Paul Pirkle. The continuous improvement program proactively educates and presents a fiber recycling method that lessens the use of natural resources, increases corporate and personal development, reduces costs and promotes safety. The secret to meeting both sustainability goals and revenue targets, the initiative is applicable to all types of paper and paperboard operations that recycle waste paper.

“Our program also builds a score carding process that effectively benchmarks, monitors and upgrades a paperboard producer’s recycling operations continuously,” Pirkle explains. “It enables us to best meet the customers’ needs in an accurate, comprehensive manner that helps them identify where the waste is generated, establish key collection procedures and set objectives that will continually to improve their waste stream’s revenue contribution to the business.”

And there is plenty of pre-consumer waste. The folding carton industry, for example, shipped about 5 million tons of product last year, and that’s just one segment of the paper industry, Pirkle points out. “One manufacturing operation in a containerboard plant can generate thousands of tons of pre-consumer, high-grade recyclable paper, production trim waste and paperboard waste annually, which in turn, can generate significant revenues for the company.”

“In the transactional, spot-buying business of paper recycling, the new initiative is something nobody else is doing in the industry,” he emphasizes. “No other company has offered as comprehensive and a value-added solution. We understand the challenges and shortcomings companies face in dealing with recycling vendors, equipment, labor and transportation issues. Recyclable materials can be wasted, which doesn’t meet anyone’s environmental goals or boost revenue. But such materials can also be a significant value-added contributor to the recycler’s profitability if professional managed, which is where we come in.”

Assessing ‘recycling health’ via survey

Based on an in-depth voice of customer study Mid America Paper Recycling conducted in late 2018, the innovative recycling management program concept was created to better understand the challenges the company’s customers face. Acting as a way to measure a customer’s “recycling health,” the audit incorporates a set of steps that are rigorously followed to divert waste, avoid expensive dumpster fees, direct important in-plant training initiatives and more to generate a significant profit for an organization.

“Continuous improvement is so important to organizations today in many other areas of their operations, so we designed this audit to bring the same strategic process to their current waste handling practices and build a smart program around them,” Pirkle notes.

The first step in the continuous improvement initiative is a new, free Waste Audit Survey, which is easy to take online in only 10 minutes but is in-depth in scope. Customers can also launch it on their smartphones via a QR code and take the survey immediately. Never having been to the potential customer’s facility, Mid America’s team can quickly determine from survey responses what an operation is dealing with, how the customer captures and recycles waste materials, what’s working and what’s not.

The survey questions also address such areas including:

- current operating procedures;

- organizational goals;

- frequency of recycling reports issued, reviewed and updated;

- waste volumes;

- how customers train staff to maintain safety, logistics, handling and efficiencies;

- revenues and financial goals;

- level of service received;

- equipment and labor involved;

- continuous improvement objectives; and

- safety, preventative maintenance programs in place

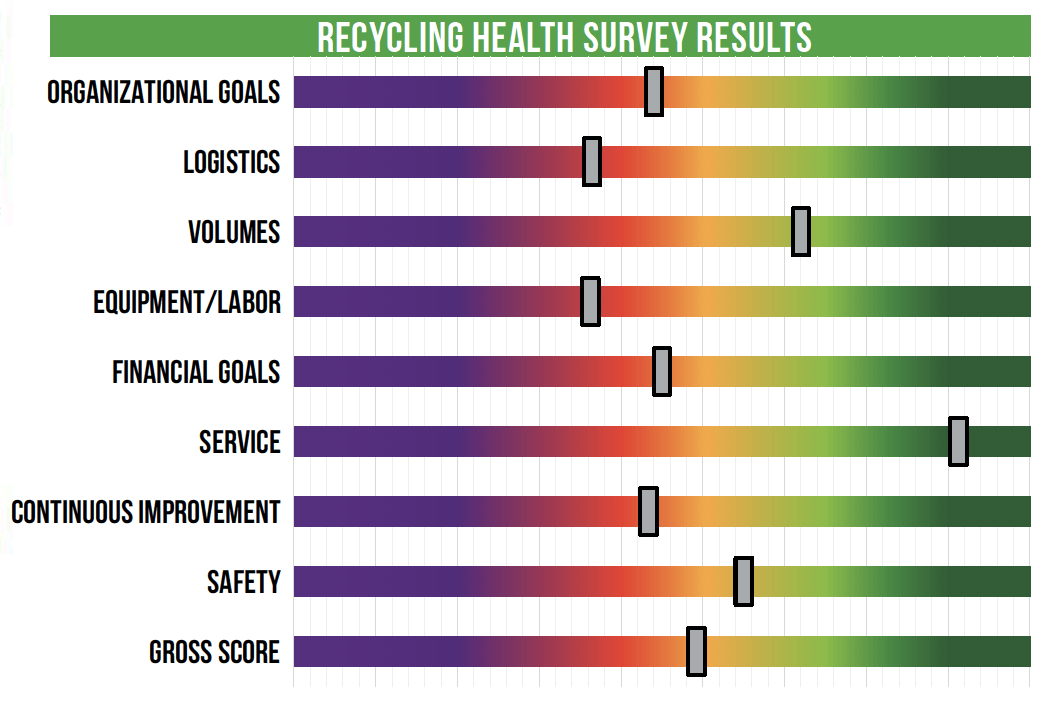

The results are associated with a point scale and then are averaged into five categories to achieve a scale percentage that determines the potential customer’s overall waste assessment grade. Mid America next sends them a report about the assessment and a plan tailored to improving their recycling processes to increase revenue growth.

Mid America’s teams then proceed with follow-up conversations, conduct onsite visits, mill assessments to match the best one to each paper grade and quarterly reviews on flow reports, rates, payments, recycling values, logistics and more.

“We also regularly track the customer’s progress in terms of revenues and environmental impacts, and the data is fed throughout the customer’s operation through regular management reports,” says Pirkle. “We find every angle out there to minimize waste, maximize returns and support customers while tracking their progress regarding the environmental aspects.”

The word is out

News about the quality initiative quickly began spreading. After debuting on Mid America’s website and in a press release on Sept. 19, Recyclingtoday.com covered the development the very same day, as did other recycling and packaging publications, e-newsletters and social media sites. More “copy” on the program soon followed.

Opportunities to help new client partners with waste stream audits are already flowing into the company though the Mid America Paper Recycling website, and meetings with potential customers are being scheduled, Pirkle says.

“The survey gives us a more strategic, overarching approach to take with potential customers. Making the survey available online and through the QR code takes us one step closer to working with that company by simply having a different conversation with them. We are encouraged that our message to educate, serve and present a clear pathway for fiber recycling is getting attention. This is only the start of something great.”

To learn more about the initiative, visit www.midamericapaper.com and to take the Waste Audit Survey, go to https://www.surveymonkey.com/r/MAPRAudit.

Leave a Reply

Your email address will not be published. Required fields are marked *