Driving Innovation in Midwest Landfills

Midwest Companies produces cost-effective road materials for landfills consisting of dieboard wood waste with help from Mid America Paper Recycling.

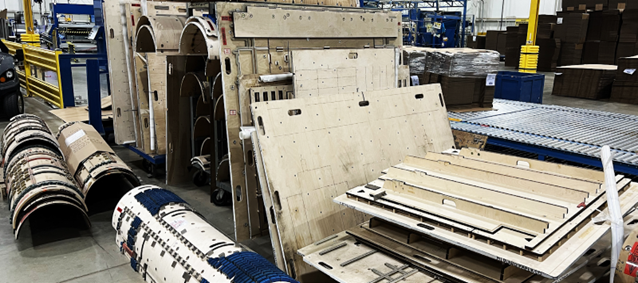

The old saying, “One man’s trash is another man’s treasure,” is nowhere more apparent than in the world of recycling. Midwest Companies, a Hampshire, IL-based manager of commercial and residential waste and recycling, consists of four companies that all have one main goal: keeping construction and demolition waste out of the country’s landfills. Midwest Companies provides disposal of railroad ties, wood waste, waste transportation, and other environmental services. Partnering with Class I, Class II & Short Line freight carriers, railroads, commercial and industrial companies, Midwest contracts with businesses across the U.S. to provide recycling services for out-of-service wood products, including used dieboards, components converters rely on for die-cutting cartons and shipping cases. Die-cutting boards form the basis of a flat or rotary cutting die into which the contours of packaging are inserted. Midwest Companies uses dieboard waste materials to manufacture TIEROC, a sustainable landfill aggregate that helps packaging converters and other wood-related businesses in meeting their sustainability goals.

Wooden dieboards used in the package converting industry to produce corrugated shipping boxes and paperboard folding cartons are often landfilled. This wood waste can often pose a potential environmental and/or safety risk. Midwest recycles the dieboards it receives from Mid America Paper Recycling using a patented technology that grinds the boards into pulp, resulting in a cost-effective alternative to traditional landfill disposal. “Tons of dieboards are all in need of recycling services,” explains Greg Kutschke, Vice President.

Mid America Paper Recycling began working with Midwest about a year ago and transports recovered dieboards to Midwest Companies in semi-trailers on an as-needed basis. “Mid America was looking for a way to recycle their expired dieboards when they contacted me,” Kutschke remembers. “I explained that we were already providing this recycling service for some years now. And we discussed how their dieboards could be recycled into a sustainable solution.”

Paul Pirkle, President of Mid America Paper Recycling said it was a real win-win situation. “We provide them with used dieboards from packaging converters,” he points out. “The boards find a new home after they’re collected and ground up with other out-of-service wood products (the metal parts are removed) to produce Midwest’s TIEROC product. This is helping us find more outlets for our hardwood dieboard recycling business.”

Mid America transports dieboards to Midwest Companies in semi-trailers on an as-needed basis. The used wood is sent through machinery that grinds it up with other wood waste materials as feedstock before being sent to TieEnergy, the company that uses a proprietary grinding process to create TIEROC. TIEROC is a biodegradable road aggregate substance used as a base for landfill roads to provide a smooth method of transport for landfill trucks, preventing them from getting stuck and causing landfill inefficiencies and wait times. This gives the wood waste a second usable life as a permeable road material that allows for efficient maneuverability within landfills.

Midwest Companies also provides its wood-grinding and recycling services as a mobile unit that can visit a site. Roads made from TIEROC last as long as the landfill needs them, not only benefitting the converters, but the landfills themselves, and the environment by diverting tons of wood waste from landfills. Mountains of this wood waste are in need of recycling services, Kutschke says. “I estimate we have received over 80 tons of dieboard waste so far that we recycled as a sustainable solution.”

A true partner

Recycling is not just a slogan or motto at either Mid America Paper Recycling or Midwest Companies, but a foundational principle. “It’s really upcycling,” Kutschke, explains. “TiEnergy works with customers to responsibly recycle and repurpose these materials, which promotes sustainability and the circular economy.

Importantly, recycling old wood materials into TIEROC—TiEnergy’s proprietary substance used to support landfill transportation—reduces hazards and is economical.”

The small investment of turning dieboards into TIEROC provides a single-source solution and an ongoing investment return. Recycling converter dieboards also opens doors to new marketable opportunities. It solves challenges for converters who want to save space by removing the boards from their operations and remediating and disposing of them properly. With Mid America Paper Recycling’s help, this makes the process happen with a financial benefit.

“We have been working with Paul and the Mid America Paper Recycling team for over a year now, and it has been going very well,” Kutschke says. “Their scheduling and delivery process continues to improve and become seamless. Their team is very responsive and a pleasure to work with.”

Wood is one of the most sustainable materials in the world. Repurposing saves space, promotes safety, and dramatically reduces landfill waste.

“Midwest Companies works really hard for us,” Pirkle sums up. “They have communicated well and actively help us move both easy and difficult loads their way. We are looking forward to continuing to provide them with dieboard waste for years to come.”

For more information on Midwest Companies’ services, visit https://www.tienergy-usa.com and https://www.mwcompanies.com. To help you assess your dieboard upcycling opportunities, contact Mid America Paper Recycling at 773-890-5454 or visit https://www.midamericapaper.com/.