Updating Employee Safety When the Heat is On

Obviously, some work environments are more dangerous than others, and "safety first" is more than just a saying. At Mid America Paper Recycling, one of our main Behaviors to remember is “Dedicate Yourself to Safety.” We try our best to stay cool in the heat, but it can sometimes be a challenge. Being proactive about safety is a must, by intervening, correcting, or speaking up about any health and safety issues.

As temperatures continue to rise in the spring and summer months, often at record-breaking levels, our changing climate affects millions of America’s workers in the pulp and paper, printing, plastics manufacturing, metals, recycling and scrap industries who are exposed to tough and potentially dangerous heat. The U.S. Department of Labor urges employers to safeguard all workers; they deserve protections.

Mid America’s plant operations struggle to stay cool in the high heat. There is always more to do when it comes to plant safety, explains Mid America’s plant manager, Alan Surdyk. “But we always remember that safety is first. Our plant can get quite hot in the summer, so we try to be aware of all our safety procedures and watch out for others in the heat as well.”

Our partners and suppliers in the pulp and paper industry are also exposed to many different hazards. But heat is the leading cause of death among all weather-related workplace hazards, according to the Occupational Safety and Health Administration (OSHA). To help address this threat, OSHA implemented a nationwide enforcement initiative on heat-related hazards. The agency’s safety message comes down to three key words: Water. Rest. Shade.

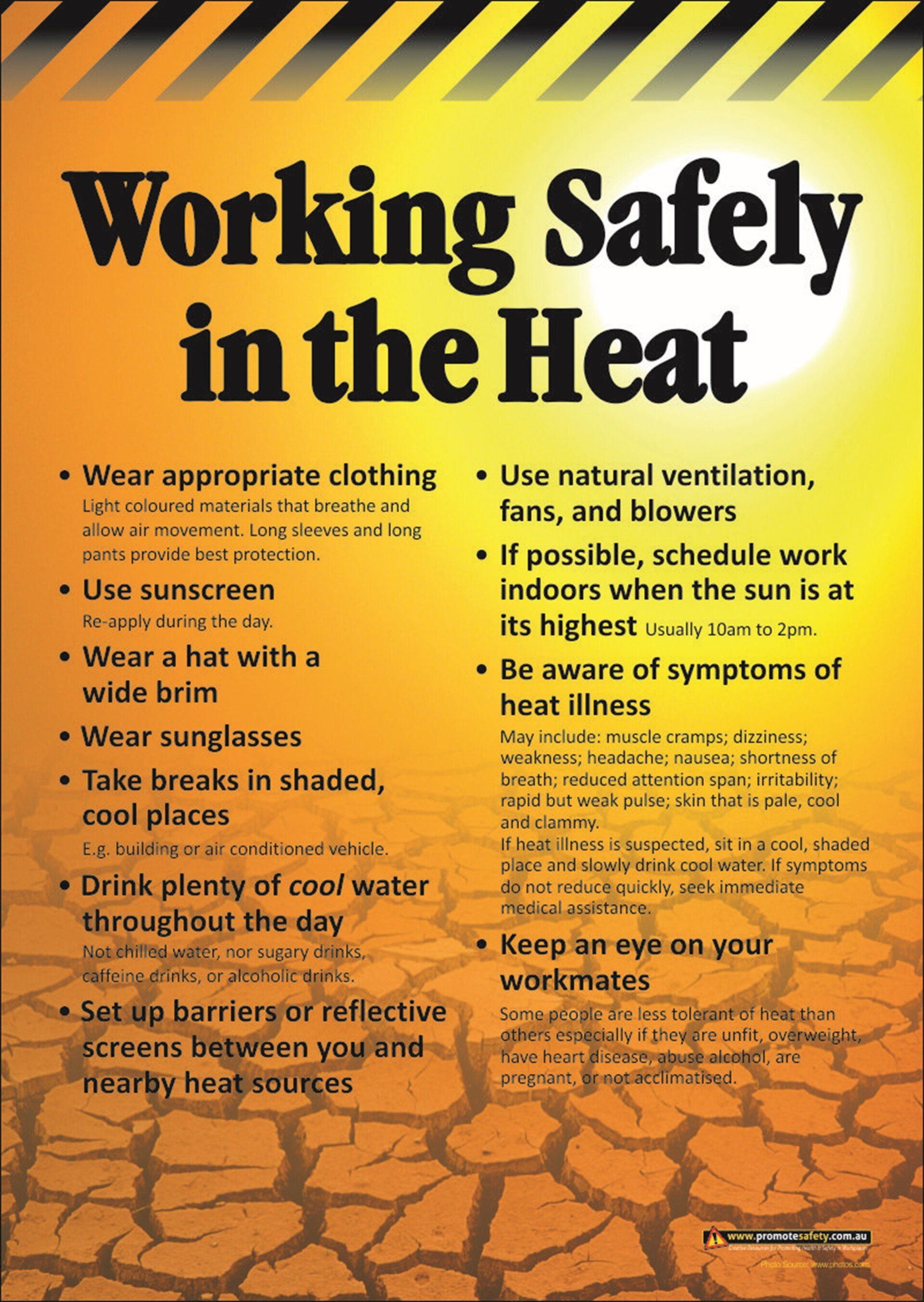

Contributors to heat-related illnesses include physical activity, high air temperatures,

Humidity, sunlight, heat sources (such as ovens or furnaces, heat-absorbing roofs, and road surfaces), air movement, clothing that hampers the body's ability to lose excess heat, such as protective gear, individual/personal risk factors, (pre-existing health conditions and lifestyle).

An employer with workers exposed to high temperatures should establish a complete heat illness prevention program. OSHA suggests:

- Providing workers with water, rest and shade.

- Allowing new/returning workers to gradually increase workloads and take more frequent breaks as they acclimatize, or build a tolerance for working in the heat.

- Plan for emergencies and train workers on prevention.

- Monitor workers for signs of illness

Even one injury is too many, as most safety experts say. When enhancing safety in the pulp and paper industry, it’s important to plan ahead, assess the risk and use the right equipment. To ensure everyone’s safety, employers must be keenly aware of the primary safety guidelines for employees working in the pulp and paper industry, and plan if the team is working in high heat conditions. Manufacturing environments with hot local heat sources, like furnaces (e.g., paper products), warehousing, boiler and electrical rooms, outdoor delivery/shipping areas and many others are often cause for heat-related illnesses.

Heat stroke is considered the most severe of heat-related illness. Workers suffering from heat stroke experience mental dysfunction such as unconsciousness, confusion, disorientation, or slurred speech. Cool these workers immediately and call 911.

Companies should ensure their workers are aware of all safety procedures, including heat protection, and that the work environment is safe. The rules must apply to everyone, and each breach in following the rules should be addressed. OSHA's

Occupational Exposure to Heat page explains what employers can do to keep workers safe and what workers need to know - including factors for heat illness, adapting to working in indoor and outdoor heat, protecting workers, recognizing symptoms, and first aid training.

And as Alan says, “We talk about the importance of doing the right thing--always. Safety is always the right thing to remember, and assisting others is one of our 2022 focuses. We are a company that focuses on continuous improvement and helping each other stay safe so we can then better WOW others. Let’s all stay safe at work this year!”